|

COMPACT PLANT AZUD WATERTECH GW DU GREY WATER TREATMENT TO REUSE IT IN TOILETS AND GREEN AREAS IRRIGATION

PRODUCTION > 2 to 9 m³/h

APPLICATIONS > Residential > Hotels > Hospitals > Public buildings |

|

||||||||||||

|

ADVANTAGES > PREASSEMBLED and FACTORY-TESTED plant. PLUG&PLAY solution. > CLOSED and LOCKED control CABINET, to prevent operation by unauthorized staff. > QUICK and EASY installation. IMMEDIATE commissioning with no setbacks. > MECHANICAL FILTRATION technologies, odorless, without waste generation and with reduced operational noise. > Exclusive pre-treatment AZUD HELIX AUTOMATIC AA, specially designed for filamentous solids. > ULTRAFILTRATION MEMBRANE system designed for high loads of TSS. > HIGH EFFICIENCY backwash system for filters and membranes, thanks to the mix water/air. > EASY operation and maintenance. |

TECHNOLOGIES

FRAMEWORK

AUTOMATION

|

MODELS

|

Model |

Code |

Production (maximum *) |

Disc Configuration |

Ultrafiltration Configuration |

Power kW |

Dimensions L x W x H (m) |

|

|

m³/h |

gpm |

||||||

|

DU2 |

71GA02A0 |

2 |

9 |

1 x 201 AA |

1 x 60" |

6.5 |

2.5 x 1.5 x 2.4 |

|

DU5 |

71GA05A0 |

5 |

22 |

1 x 201 AA |

2 x 60" |

7.9 |

3.2 x 1.7 x 2.4 |

|

DU9 |

71GA09A0 |

9 |

40 |

1 x 202 AA |

4 x 60" |

13.5 |

4.5 x 1.7 x 2.4 |

* Design criteria: Turbidity = 25 NTU; TSS = 50 mg/l; T = 20ºC │Dimensions without auxiliary equipment. L=Length; W=Width; H=Height.

MAIN COMPONENTS

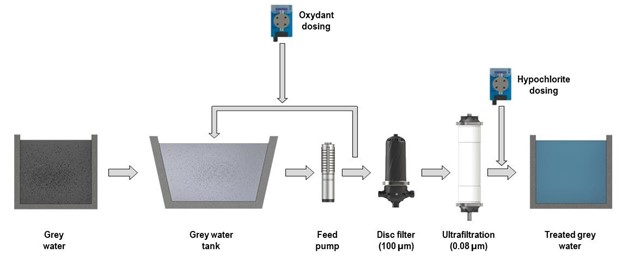

> Stainless steel submersible grinder FEED PUMP.

> Digital DOSING PUMP for OXIDANT.

> AZUD HELIX AUTOMATIC AA disc filter (100 μm) with air assisted backflushing.

> PVDF ULTRAFILTRATION membranes (0.08 μm), housed in PVC vessel.

> Ultrafiltration BACKWASH SYSTEM; included pump, blower, tank and dosing pump.

> RESIDUAL CHLORINATION for the treated water disinfection.

> PLC with touch screen. Pressure and flow monitoring.

> Electric cabinet including transformer, circuit breakers and motor starters.

> Metallic CONTROL CABINET with key lock. Included additional framework for disc filter and UF membranes.

OPTIONS

REMOTE CONTROL system.

ModBus communication

WATER QUALITY

| RAW WATER |

GREY WATER from sinks, shower basins and baths. > High level of suspended solids > High level of organic matter > High level of pathogens |

|

||||||||||||||||||||

| TREATED WATER |

Meets the requirements for GREY WATER RECYCLING in toilets and green area irrigation. > TSS ≤ 10 mg/l > Turbidity ≤ 2 NTU > BOD5 ≤ 50 mg/l > E. Coli ≤ 10 CFU/100ml > Residual chlorine: 0.5 – 2.0 mg/l |

|||||||||||||||||||||

TREATMENT LINE

INSTALLATION REQUIREMENTS

| POWER SUPPLY |

Three-phase // 380 - 400 V AC // 50 Hz. |

| FOOTPRINT |

According to plant dimensions. One meter free space around the plant for operation and maintenance to be considered. |

| STORAGE TANKS |

Grey water and treated water. |

| OPERATION PARAMETERS |

> Inlet pressure: 2 - 4 bar > Room temperature: 0 - 40 ºC > Water temperature: 5 - 30 ºC |

NOTE: In order to assure the treated water quality and nominal production for each model, a COMPLETE and UPDATED CHEMICAL-PHYSICAL ANALYSIS of the raw water is RECOMMENDED. This analysis will be requested before manufacturing the plant.

|

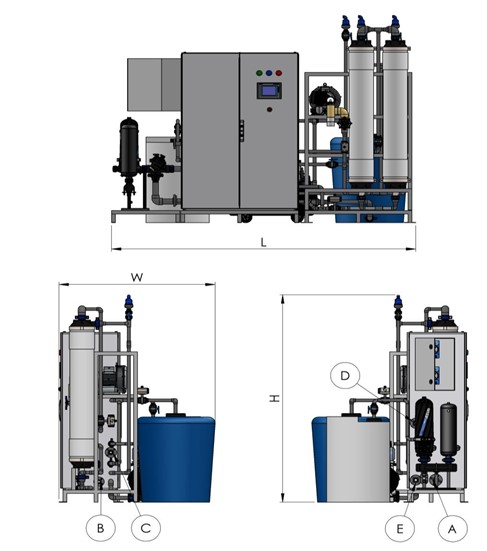

Model |

Dimensions L x W x H (m) |

Connections* |

||||

|

Inlet (A) |

Drain (B) |

Outlet (C ) |

Crossflow (D) |

Recirculation (E ) |

||

|

DU2

DU5

DU9 |

2.5 x 1.5 x 2.4

3.2 x 1.7 x 2.4

4.5 x 1.7 x 2.4 |

1" / 32 mm

1 1/4" / 40 mm

1 1/2" / 50 mm |

1 1/2" / 50 mm

1 1/2" / 50 mm

1 1/2" / 50 mm |

1" / 32 mm

1 1/4" / 40 mm

1 1/2" / 50 mm |

1" / 32 mm

1" / 32 mm

1" / 32 mm |

1" / 32 mm

1" / 32 mm

1" / 32 mm |

* DIN Flanges Hydraulic Connections; check size for ANSI flange.

|

ACROSS THE WOLRD |

|

|

|

|

|

|

|

Texts and graphs published with the kind permisson of the supplier.