PROJECT DATA

|

|

A spunlace process is used at a well-known medical care company in the manufacturing of nonwoven products. Using this technology, fibers or filaments of unconsolidated nonwovens are swirled, intertwined and thus consolidated by means of high pressure water jets emerging from nozzles. The original nonwovens have high strength and softness. The quality of the process water plays a decisive role in this process. Its condition influences the service life of various machine parts and the jet strips.

SOLUTION

Effective particle removal

AZUD HELIX AUTOMATIC disc filters were used to filter the process water. The filter function of these filters has a threefold effect, namely as a surface filter, depth filter and cyclonic separator. The HELIX technology not only enables precise dirt separation, but also extremely efficient cleaning of the disc filter modules.

Process improvement:

- The rinse water consumption could be reduced by more than 50% compared to the previously used automatic backwash filters, which brings the company savings of around 13500 € per system and year (at a water price of 4.50 €/m3).

- Manual cleaning or the replacement of downstream bag filters can now largely be dispensed with.

- The bag filters are only used as safety filters. The filters are not blocked.

- The nonwoven machines in the spunlace process work trouble-free. The cleaning intervals could be increased from 3-active to 7-active.

- The high pressure pumps (40 bar) tolerate the filtered water well. There are no negative effects.

TECHNOLOGY

|

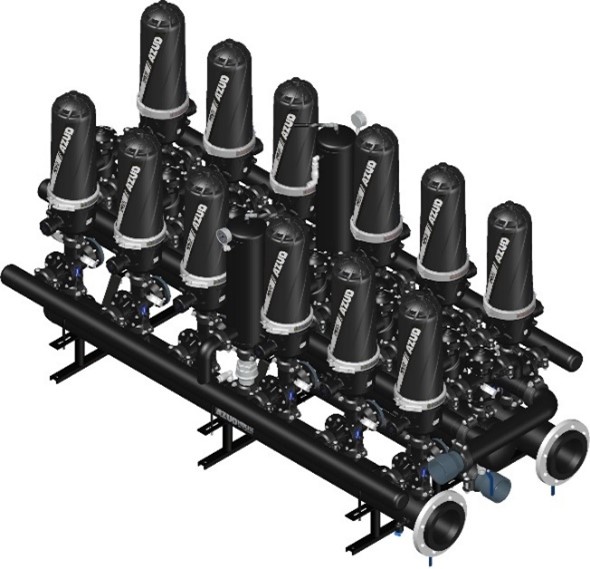

AZUD Disc Filter The installed pressure disc filters AZUD HELIX AUTOMATIC with twelve filtering elements and a filter grade of 20 μm have a nominal flow rate of 72 m3/h and a filter surface of 19440 cm2. The filter elements consist of a stack of finely grooved filter discs made of plastic, which are pressed onto one another by spring pressure. The raw water passes from the outside to the inside through the disc stack through a helix anticlogging device, which creates centrifugal motion. As a result, particles are kept away from the filter discs in a rotary motion and the frequency of backwashing is reduced. Bigger particles remain outside on the surface of the disc stack, while smaller particles are trapped in the grooves. The backwashing is triggered automatically via differential pressure, time, external signal or manually and takes place during the filtration stage. In this way, the filtration production is maintained even during backwashing |

|

Better technology brings practical benefits:

- AZUD HELIX AUTOMATIC filters work with the lowest differential pressure thanks to their large surface

- A stable low differential pressure is achieved through efficient backwash mechanisms and saves energy costs

- No risk of breakthroughs

- Fully automatic operation

- Regeneration of the filter discs without interrupting operation

- No recontamination during backwashing due to the use of pure water

- Short rinsing intervals due to the expansion effect of the stack of the discs

- Robust materials ensure long service life and minimal maintenance

- Adaptation of the filter characteristics by exchanging the discs in case of changed media or process requirements is easily possible

- Different filter grades of the filter discs: 5 /10 /20 /50 /100 /130 /200 /400 micron