Barrier filters are filter systems that remove solid particles from the liquid-solid mixture by means of a barrier. A barrier is constructed from various materials such as textile or wire mesh, porous plastics or sintered materials and forms a porous permeable layer (filter media) which retains particles larger than the pores.

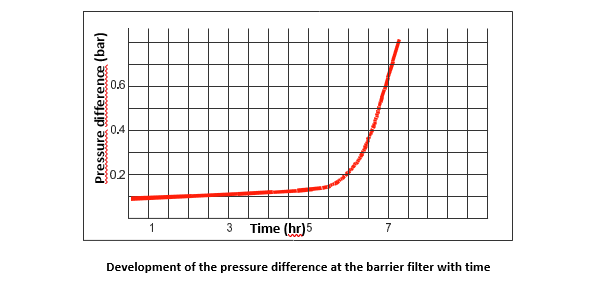

The driving force is the pressure difference between the two sides of the barrier. After flowing through the filter cake, the filtered liquid is called filtrate. The particles deposited on the barrier build up into a porous solid compound, the filter cake. When the filter cake builds up, it takes over the filtration process, which leads to increasing pressure losses during operation. For this reason, the filter fineness of the filter must be selected in such a way that the retention of the particles to be separated is guaranteed. On the other hand, it is important to keep the pressure difference input as minimal as possible. If the filtrate volume flow becomes too low due to the constantly increasing pressure difference during operation, the filter cake should be removed. This can happen either by changing the filter material or by backwashing.

In case of the conventional barrier filters such as filter bags or cartridges, the filter material has to be replaced with a new one, which leads to a regular interruption in the filtration performance. Ongoing personnel and material costs are incurred.

|

|

|

Barrier filters – Cartridge filter housings and wrapped filter cartridges |

|

|

|

| Barrier filters – Bag filter housings and filter bag | |

On the other hand, automatically self-cleaning filters such as mesh filters or pressure disc filters guarantee a continuous filter capacity, since backwashing takes place during the filtration process. Trouble-free continuous operation is possible for many years. In addition, there are no material costs, so the filter systems pay for themselves within a short time.

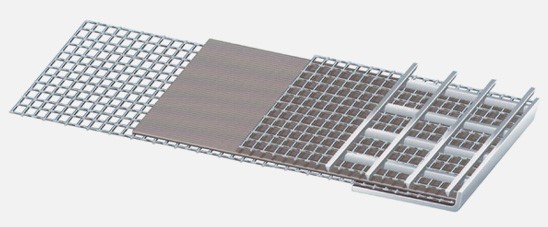

Mesh filters have a network of metal wires that form a flexible filter fabric with precise, rigid pore openings. Various materials are used as filter material, such as stainless-steel wire mesh, wedge wire mesh or perforated screen with different supporting mesh layers made of PVC, PP or stainless steel.

Mesh with support layer

The filtration works according to the principle of surface filtration. The water enters the system and flows inside the mesh filter through the mesh, causing the particles to collect on the inside of the filter element. The already filtered water can be drained through the outlet opening. As soon as the differential pressure rises, the flushing cycle starts. A hydraulic valve opens at the drainage outlet, which in turn triggers the suction of the inner nozzles. This, together with the spiral movement along the mesh, sucks in the filtered particles. The particles are discharged down the drain.

Self-cleaning mesh filter AZUD LUXON LDB

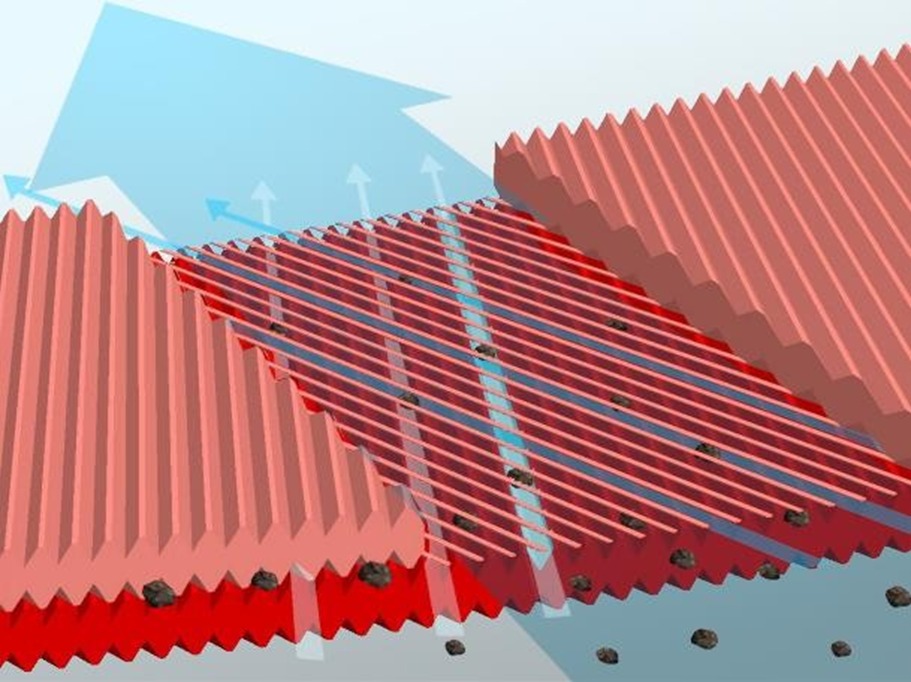

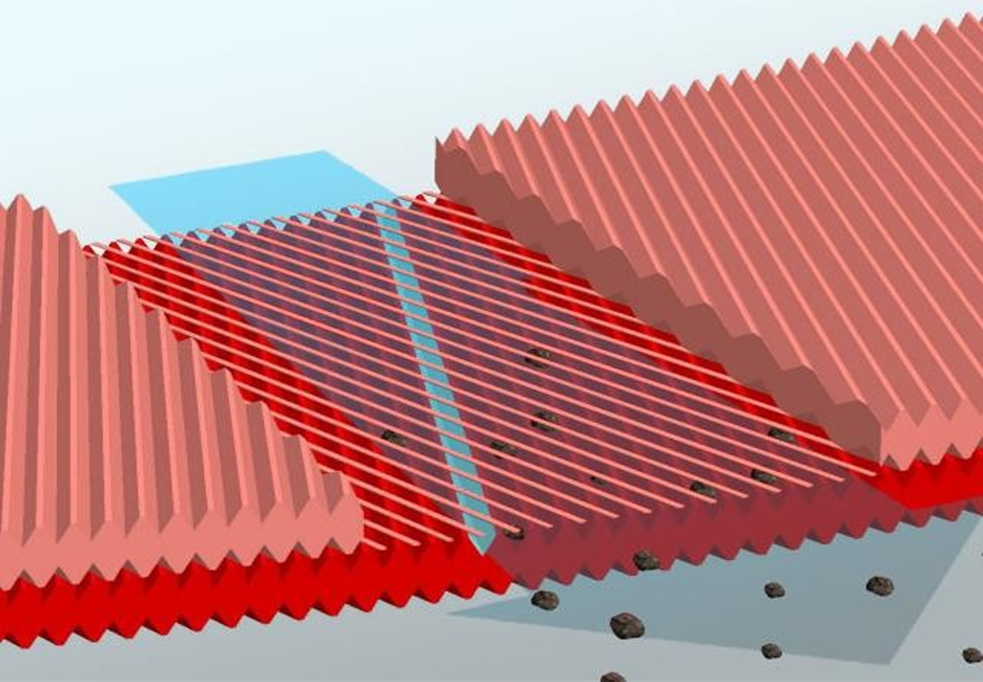

Pressure disc filters have filter elements that consist of a stack of finely grooved plastic discs that are pressed together by a spring pressure. This concept combines the principle of surface and depth filtration in order to achieve maximum efficiency and safety. The special geometry of the grooves on the filter disc results in a variable cross-section of the open water path, which means that round and long particles are reliably retained when they pass through the stack of discs.

|

|

|

Retention of particles on the surface and in the outer circumference of the filter discs |

|

The water passes through the disc stack from the outside inwards, larger particles remain on the outside on the surface, smaller ones get stuck in the grooves. Only particles that are absolutely smaller than the nominal filter grade can pass through the element. During backwashing, the water flow is reversed by means of 3-way valves in the filter, so that the water flows into the filter against the normal flow direction. Due to the special design of the filtering element, the water pressure compresses a spring in the head of the element, relieving the pressure on the disc stack. Water nozzles are integrated into the frame of the element, the flushing water now sprays against the filter discs from the inside, causing them to rotate. This results in a combined cleaning by the rinsing effect and a mechanical cleaning by the friction of the discs with each other.

Self-cleaning disc filter AZUD HELIX AUTOMATIC