Filtration through granular materials is the oldest technical water treatment process. The objective is the separation of solids from a liquid, which is accomplished by forcing a solid-loaded fluid to flow through a porous permeable layer (filter media) that retains the solid particles. In this way, either a solid-free liquid or a solid with as little liquid as possible is obtained. Various transport processes such as diffusion or sedimentation, attachment mechanisms through adsorption, electrical, chemical and intermolecular forces and shearing processes play a role in filtration. The particles to be removed must first be transported in the immediate vicinity of the filter grains before they can be held there by accumulation processes. After separation on the filter grain, however, it is possible for particles that have already accumulated to be resuspended in the liquid due to shear forces. This fact is used in practice to clean the filters by backwashing. In general, a distinction is made between cake filtration, cross-flow filtration and depth filtration.

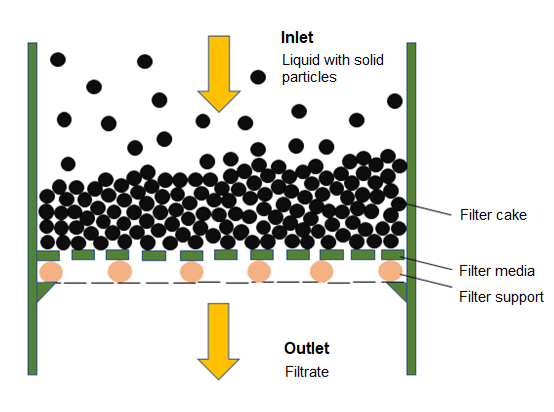

Cake filtration

Cake filtration is characterized by the formation of a filter cake. The liquid-solid mixture passes through a porous filter medium, which retains the solid parts. The particles deposited on the filter media form a porous solid compound, the filter cake. When the filter cake builds up, it takes over the filtration process, which leads to increasing pressure losses. After flowing through the filter cake, the filtered liquid is called filtrate. Textile or wire mesh, porous plastics or sintered materials are used as filter media. The driving force for cake filtration is the pressure difference between the two sides of the filter bed. The choice of the filter medium depends on the porosity, so that the retention of the particles to be separated is guaranteed. On the other hand, the flow must be made possible with a minimum pressure difference input. In the case of continuous processes, the filter medium must be regularly regenerated with backwashing in the opposite direction. Cake filtration is used, for example, in waste water systems.

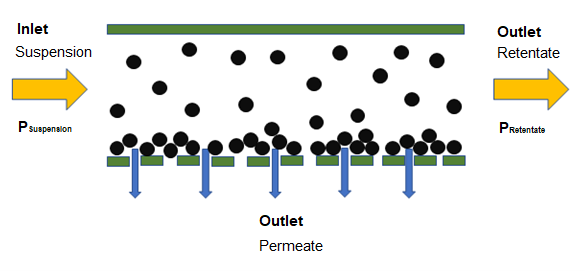

Cross-flow filtration

Contrary to cake filtration, in cross-flow filtration the liquid-solid mixture to be filtered is not fed directly through the porous filter medium under pressure, but parallel to the filter medium layer. The cleaned liquid drawn off by the difference in pressure is referred to as permeate, and the concentrated stream that emerges is referred to as retentate. The separation of particles on the surface of the filter medium that are larger than the pore size of the filter medium results in the formation of a cover layer. The turbulent flow of the medium flowing past prevents further filter cake formation, the separation and removal of the particles is in balance. Cross-flow filtration is suitable for very fine substances. Very fine membranes or fabrics are used as filter media. Depending on the particle size, a distinction is made between microfiltration (particle size 0.1-100 μm) and ultrafiltration (particle size 0.005-0.1 μm), which are implemented in different module designs, e.g. plate modules, tube modules and wound modules.

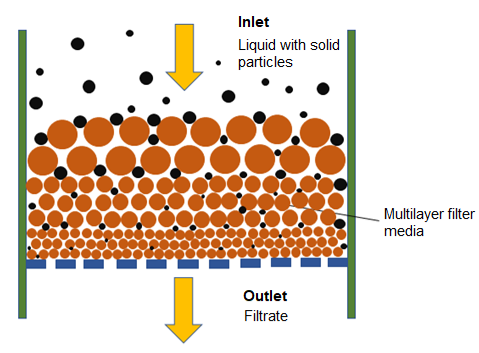

Depth filtration

The principle of depth filtration is based on the storage of the solid particles in a bed of coarse particles up to 3 meters height. The particles to be separated are significantly smaller than the filter particles and the pores created in the bed. The bulk material is flowed through from top to bottom by gravity or overpressure, with the actual cleaning process taking place as the particles adhere to the filter medium. Depth filters are normally used in applications with high dirt loads thanks to their service life.

The filters can be distinguished by the pressure applied or by the flow rate. Depth filters for liquids, which rely on gravity flow, often have very large areas of up to 10,000 m2. The liquid to be filtered forms a layer of liquid up to 1.5 m height on the filters, which allows it to flow through the filter due to the hydrodynamic pressure. The filtration speed is low (0.1-0.5 m/h). Pressure depth filtration is carried out under overpressure and at higher speeds (3-10 m/h). Depth filters are backwashed in the opposite direction, causing the filter medium particles to be whirled up and fluidized. In order to increase the effectiveness of cleaning the filter, air can also be supplied.

Membrane filtration

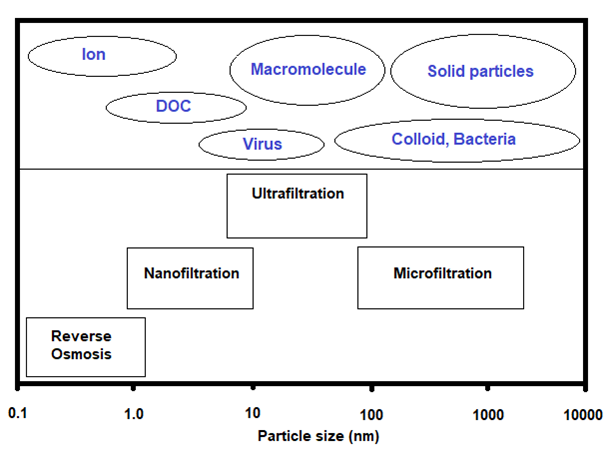

With membrane filtration, the water is pressed through the membrane material due to a pressure difference and troublesome substances are removed. The water components to be separated with a diameter that exceeds the pore size of the membrane are deposited on the surface. Depending on the size of the particles to be separated, four different processes are distinguished: microfiltration, ultrafiltration, nanofiltration and reverse osmosis.

Microfiltration is often used in food technology, the pharmaceutical industry, in waste water treatment and as a preliminary stage to reverse osmosis to protect the membrane from clogging. Mainly suspended particles are separated, but also algae and viruses. The required pressure difference is adjusted to between approx. 0.1 bar and 3 bar for a pore size > 100 nm.

Ultrafiltration is mainly used in drinking water treatment. Particles with a size between 10 and 100 nm are retained. The required pressure difference is 0.1 bar to 5 bar.

Nanofiltration is used to remove humic substances, sulphate, hardeners and organic trace substances such as pesticides. The areas of application largely overlap with those of ultrafiltration and reverse osmosis. The pressure is between 3 and 20 bar.

Reverse osmosis is used in practice for the treatment of boiler feed water and seawater, whereby both polyvalent and monovalent ions with a size of 0.1-1 nm can be retained in the membrane. The required high pressures lie between 10 and 100 bar.