4DCL – disc filter

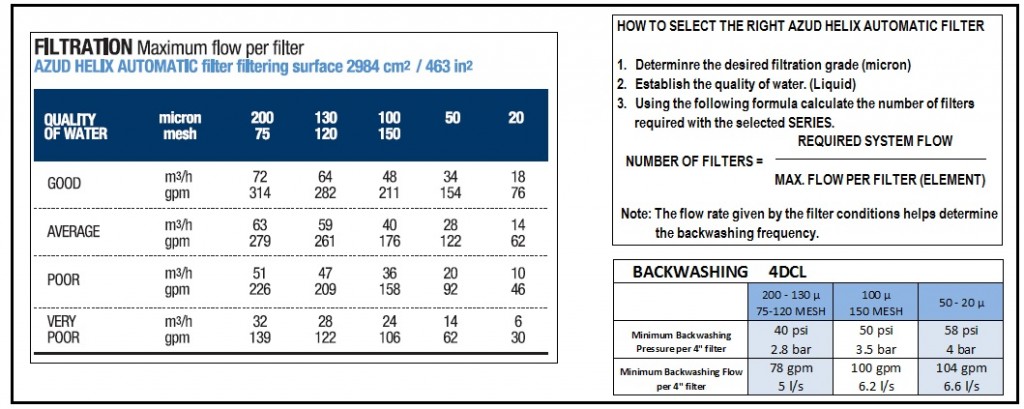

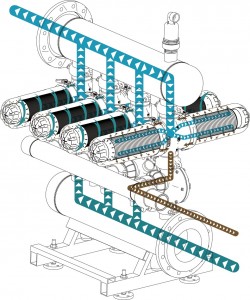

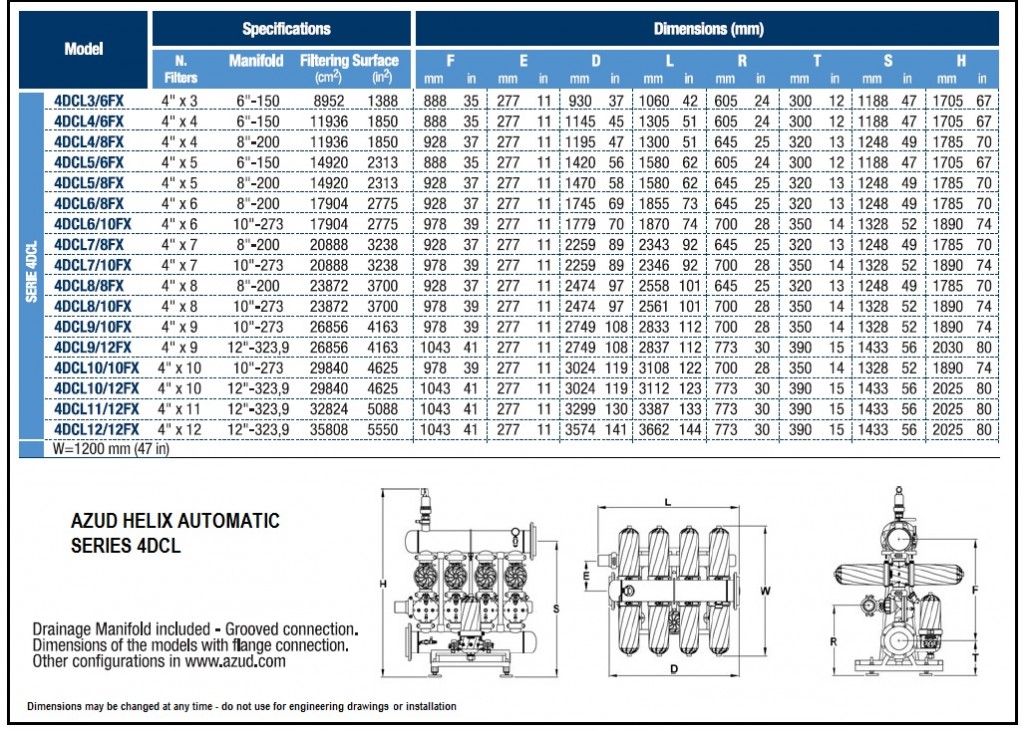

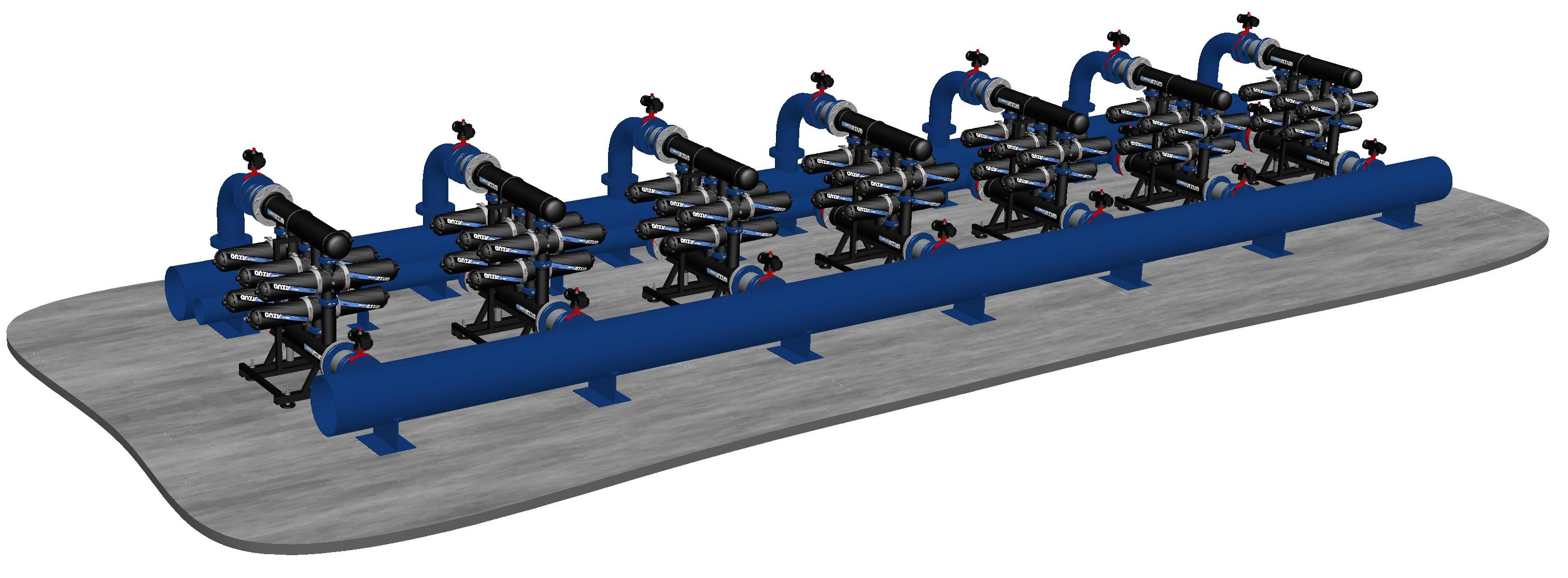

Automatic in-line Self Cleaning equipment combining multiple twin disc filter elements. Each double element is controlled by one 3″ three way valve. High Density Polyethylene manifolds. Easy to install. Maximum resistance and durability. Max flow 2530 gpm.

Modular configuration allows design according to customer preference or space availability.

Automation available in 110 V, There are special options available for Low Pressure, High Pressure and Sea/Saline water conditions. Also possible to backwash with compressed air, minimizing the water loss during backwash (Air Assist Option – AA).

ADVANTAGES

FILTERS ALL KINDS OF PARTICLES

Organic , in-organic, and fibrous

FILTRATION AND BACKWASH OCCUR SIMULTANIOUSLY

Only a portion of the water is used for backwash in multi element systems.

LARGE FILTRATION SURFACE AREA

DISC DESIGN

The discs are available in Multi-Groove (MG) or Wall type depending on the application they are needed for. The MG discs provide depth filtration resulting in very high efficiency at a given micron level.

The width and support structure of the discs provided high resistance to the pressure differential across the filtration surface.

The superior quality of the injection molding of the discs provides uniformity of the discs which results in high efficiency at the selected micron level.

HELIX SYSTEM

The Helix is a centrifugal action device on the inlet to the filtering element which forces the inlet water to spin around the discs inside the filter housing, this forces the larger particles away from the discs reducing the accumulation of solids on the filtration surface, thus optimizing the performance of the discs and reducing the frequency of backwashing.

AIR ASSIST

AA backwashing option available on all models.

COMPACT DESIGN

Vertical design allows for smaller footprint.

MODULAR, VERSATILE, COMPATABLE

The system permits a wide range of configurations with a minimal number of components. Vertical or horizontal design.

AUTOMATIC CLEANING OF FILTER ELEMENTS

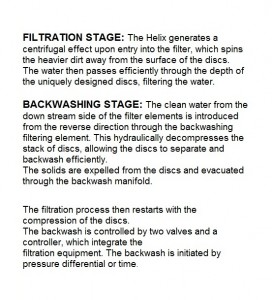

Filtration Stage: The Helix generates a centrifugal helical effect upon entry into the filter, this moves the particles away from the discs. The water then passes efficiently through the depth of the uniquely designed discs.

Backwashing Stage: The clean water from the down stream side of the filter elements is introduced from the reverse direction through the backwashing filtering element. This hydraulically decompresses the stack of discs, allowing the discs to separate and backwash efficiently.

The solids are expelled from the discs and evacuated through the backwash manifold.

The filtration process then restarts with the compression of the discs.

The backwash is controlled by two valves and a controller, which integrate the

filtration equipment. The backwash is initiated by pressure differential or time.

LOW MAINTENANCE

No tools required. Very few warring parts

MANUFACTURED IN PLASTIC

The patented design and the materials used in manufacturing the filters guarantee a long life with high resistance.

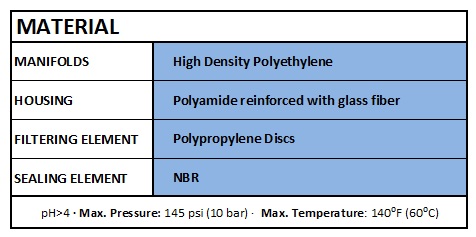

The maximum operating pressure and temperature of the standard equipment is 145 psi at 140⁰F.

WATER AND ENERGY SAVINGS

Amount of water used during backwashing cycle is significantly less than with other types of automatic cleaning filters. Time between backwashing cycles is increased by the design of the Helix system.

QUALITY CONTROL

All products go through stringent quality control before leaving the factory.

FACILITATES EASY TRANSPORTATION AND INSTALLATION

Equipment is shipped pre-assembled (Only limited assembly requird on site)

ADDITIONAL INFORMATION

Backwashes only one station at a time. The remaining stations stay in filtration mode and continue to supply clean water to the process

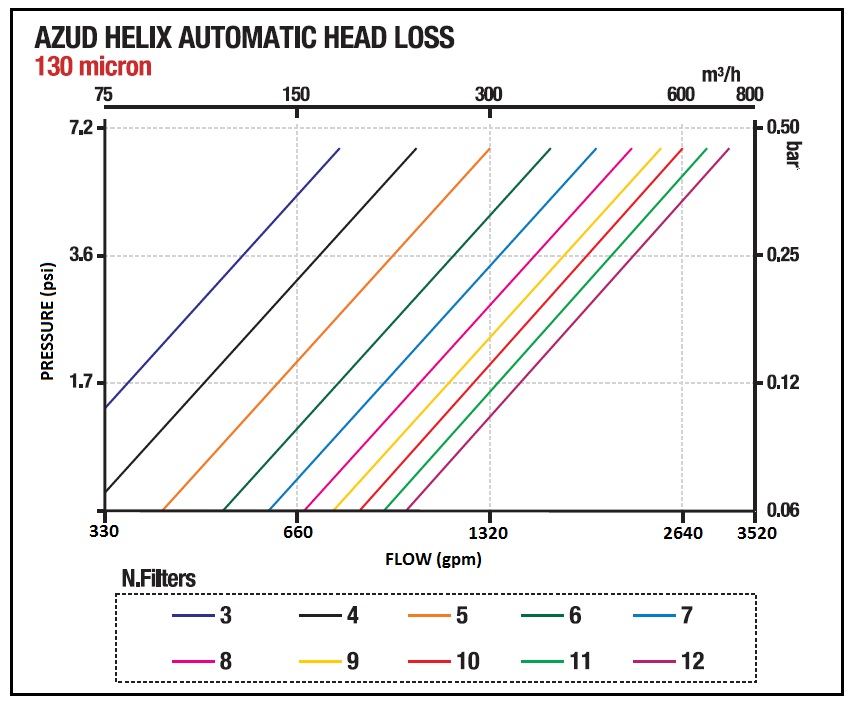

Available in 6” through 12″, with flows up to 2530 gpm (with 130µ discs).

Maximum Operating Pressure: 145 psi

Maximum Operating Temperature: 140⁰F

Disc options – 5µ, 10µ, 20µ, 50µ, 100µ, 130µ, 200µ and 400µ.

TECHNOLOGY

TECHNICAL DATA

We offer the AZUD 4DCH for large quantities of water, for further information do not hesitate to contact us!

Texts and graphs published with the kind permission of the supplier.

Texts and graphs published with the kind permission of the supplier.